Industrial Wide-Belt Sanders

Wide-Belt Sander Heavy Duty Industrial Wide-Belt Sanders

Feature Overview: Our industrial wide-belt sanders feature a wide range of working widths, adjustable working thickness, infeed and outfeed, heavy-duty hinged access doors, intuitive/durable control panel, leveling feet, lift points, and are available in different head configurations.

Our high-flow air handling compatibility gives our industrial wide-belt sanders impressive performance for dust collection. Safety features include heavy duty disc brakes for emergency stop. (see individual product pages for additional specifics)Wide-Belt Sanders can improve the efficiency of any finish line, or wood production. With a multi-head wide belt sander, swift, single pass sanding is possible.

Industrial Belt Sander Electrical Requirements: Operating voltage: 460 Volt/60Hz/3 Phase (check with us for other options).

** Also available in a Double Head configurationOur Wide Belt Sanders

- Wide Belt Sander Top Surface Sander Triple – Belt Sander Roller + Combination

- WTM-QSG Series Top Surface Sander Triple – Belt Sander Roller + Combination

- Heavy Duty 4 sided Moulder WTM-DSG Series Bottom Surface Sander Triple-belt sander roller + combination

- WTM-FSG Series Constant Pass-Line, Top Surface Sander Triple-belt sander roller + combination

- Medium Duty Wide Belt Sander

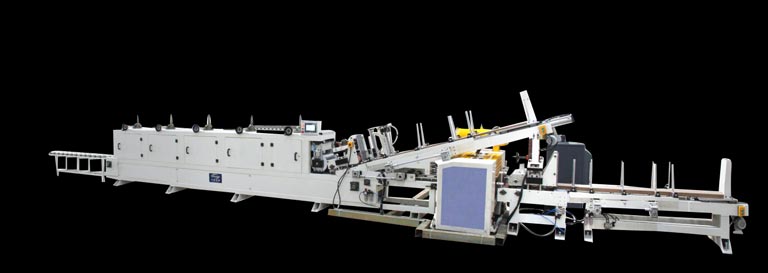

Automatic Finger Jointer Line

Model:

WTM-1560x600IIGModel Name:

Automatic Finger Jointer lineMF756A Infeed strap conveyor:

Working table Length: 1150mm

working table width: 600mm Motor power: 0.375kwMXZ3515-II Auto finger shaper:

Table size: 850W x 600L mm

Max. working size: 850L x 80W x 150H mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8

Mpa Total power: 16.12kwMF756B Middle strap conveyor:

Working table Length:1150mm

working table width: 600mm

Motor power: 0.375kwMXZ3515T-II Auto finger shaper(glue-spreading):

Table size(W x L): 850 x 600 mm

Max. working size(L x W x H): 850 x 80 x 150mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8 Mpa

Total power:18.74kwMF746 Roller output conveyor,

MF761 Chain conveyor@2sets

(Include 1 set Tipper)MHZ 1560 Auto finger joint assembler:

Max. working size: 6000L x 150W x 80H mm

(1times can make 2 workpiece)

Min. working size: 1500L x 30W x 20H mm

Main saw blade size: 355mm

Working air pressure: 0.8 Mpa Max.

Jointing force: 7800kg

Total power: 8.45kwGang Rip Saw

Model Name: Movable Gang Rip Saw

Model:

WTM-RIP350Specification:

1. Max. cutting width: 350mm

2. Max cutting thickness: 10-100mm

3. Min. working length: 750mm

4. Number of saw blade: Movable 3 blades

5. Saw blade dia.: 300-400mm

6. Spindle rotation speed: 4200 rpm

7. Blade adjustment speed: 44-66 m/sec

8. Feeding motor speed: 6-48m/min

9. Number of saw blades: 6 blades

10. Saw spindle dia.: 65mm

11. Number of pressure rollers: 4

12. Electronic lasers for each bladeElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseDenibbing Machine

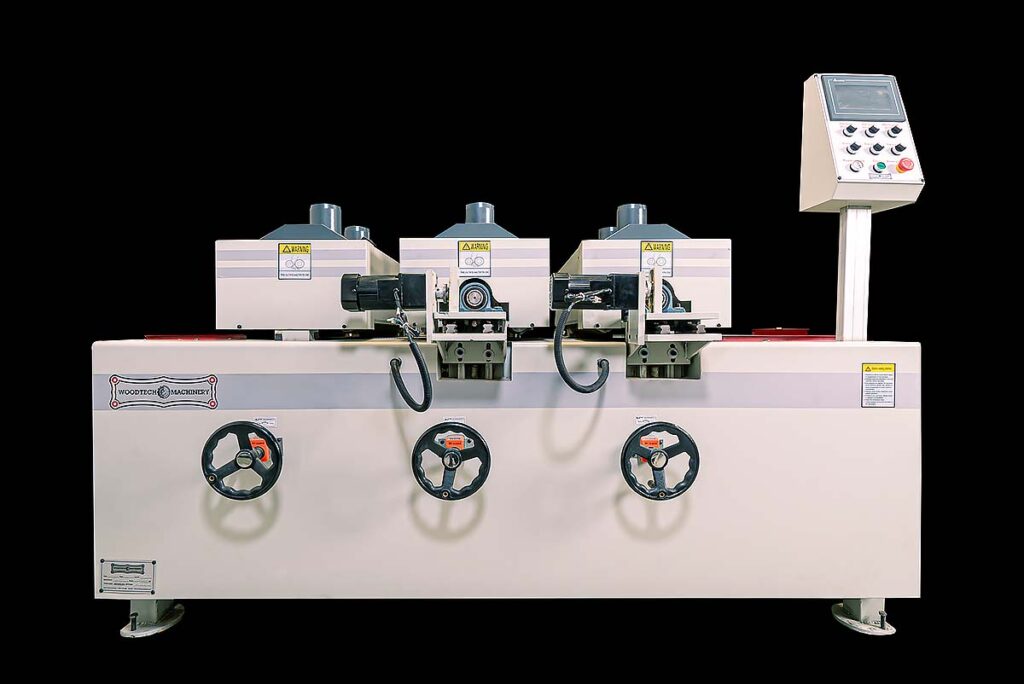

Model: WTM-UVDB Series

Model Name:

Denibbing/sanding machine. This machine is for denibbing/sanding of wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2-6 head configurations

5. Working height: 800mmFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple sanding grits, and brush lengths available

Optional – Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Wire Brushing/Denibbing Machine

Model: WTM-UVWB Series

Model Name:

Wire brushing/ Denibbing Sanding MachineApplication:

Wire brushing, embossment, texturing, of the grain in wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in 2-6 head configurationsFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple wire diameter and bristle lengths available

* Optional -Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseWide Belt Sanders

WTM-QSG Series Top Surface Sander Triple – Belt Sander Roller + Combination

Features:

Working widths: 24”, 42”, 51”Service side: left

Enclosed MotorsBrush unit for cleaning panels after sandingGeneral Technical Data:

WTM-QSG series machine is a precision sander with a movable feed belt for the thickness setting.

Working thickness: 3/16” – 4”

Minimum working length: 13”

Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units:

Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control. Press rollers assure the flatness of the boards for an even sanding is suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.

-Hard Rubber roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.

-Steel roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.

-Pad can be adjusted up and down.

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configuration

Wide Belt Sanders

Heavy Duty 4 sided Moulder

WTM-DSG Series Bottom Surface Sander

Triple-belt sander roller + combinationFeatures: Working widths: 24”, 42”, 51”

Service side: left Enclosed Motors

Brush unit for cleaning panels after sandingGeneral technical data: WTM-DSG series machine is a constant pass-line, bottom sanding machine, it is specially designed for a sanding line with a fixed height.Working thickness: 3/16” – 4”

Minimum working length: 13”

Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units: Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control.

Press rollers assure the flatness of the boards for an even sanding Is suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.

-Hard Rubber roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.

-Steel roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.

-Pad can be adjusted up and down.

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configurationWide Belt Sander

WTM-FSG Series Constant Pass-Line, Top Surface Sander

Triple-belt sander roller + combinationFeatures:

Working widths: 24”, 42”, 51”

Service side: left

Enclosed Motors

Brush unit for cleaning panels after sandingGeneral technical data:

WTM-FSG series machine is a constant pass-line sanding machine, it is specially designed for a sanding line with a fixed height

Working thickness: 3/16” – 4”

Minimum working length: 13”Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units:

Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control.Press rollers assure the flatness of the boards for an even sandingIs suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.-Hard Rubber roller is available. (optional)-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.-Steel roller is available. (optional)-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.-Pad can be adjusted up and down.-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configurationPUR Glue Line

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

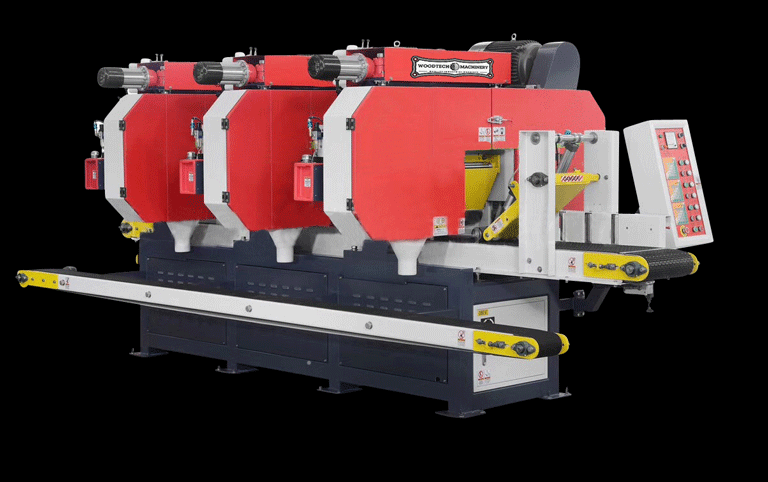

2-3 -4 sections pressing rolls: AluminumHorizontal Band Saws

Model:

WTM-400Z2 and WTM-400Z3Model Name:

Two or Three heads HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5-130mm

Width of conveyor belt: 375mm

Diameter of saw roller: 711mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW x 2 or 3 depending on the model

Approx Overall dimension: 2800L x 2200W x 2000H