Automatic Finger Jointer Line

Model:

WTM-1560x600IIGModel Name:

Automatic Finger Jointer lineMF756A Infeed strap conveyor:

Working table Length: 1150mm

working table width: 600mm Motor power: 0.375kwMXZ3515-II Auto finger shaper:

Table size: 850W x 600L mm

Max. working size: 850L x 80W x 150H mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8

Mpa Total power: 16.12kwMF756B Middle strap conveyor:

Working table Length:1150mm

working table width: 600mm

Motor power: 0.375kwMXZ3515T-II Auto finger shaper(glue-spreading):

Table size(W x L): 850 x 600 mm

Max. working size(L x W x H): 850 x 80 x 150mm

Min. working size: 200L x 30W x 20H mm

Shaper spindle diameter: 70mm

Shaper blade diameter: 160mm

Main saw blade size: 255mm

Shaper spindle speed: 5000 rpm

Main saw spindle speed: 2840 rpm

Working air pressure: 0.8 Mpa

Total power:18.74kwMF746 Roller output conveyor,

MF761 Chain conveyor@2sets

(Include 1 set Tipper)MHZ 1560 Auto finger joint assembler:

Max. working size: 6000L x 150W x 80H mm

(1times can make 2 workpiece)

Min. working size: 1500L x 30W x 20H mm

Main saw blade size: 355mm

Working air pressure: 0.8 Mpa Max.

Jointing force: 7800kg

Total power: 8.45kwGang Rip Saw

Model Name: Movable Gang Rip Saw

Model:

WTM-RIP350Specification:

1. Max. cutting width: 350mm

2. Max cutting thickness: 10-100mm

3. Min. working length: 750mm

4. Number of saw blade: Movable 3 blades

5. Saw blade dia.: 300-400mm

6. Spindle rotation speed: 4200 rpm

7. Blade adjustment speed: 44-66 m/sec

8. Feeding motor speed: 6-48m/min

9. Number of saw blades: 6 blades

10. Saw spindle dia.: 65mm

11. Number of pressure rollers: 4

12. Electronic lasers for each bladeElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseStraight Line Rip Saw

Model: WTM-SLR460

Model Name: Straight line rip saw

Specification:

Working Thickness: 10-90mm

Min. Working Length: 200mm

Max. Working Width: 460mm

Main Motor Power: 11kw

Feeding Motor Power: 1.5kw

Elevation Motor Power: 0.25kw

Total Motor Power: 12.75kw

Feeding Speed: 10-33m/min

Spindle Speed: 2900 rpm

Saw Blade Dia.: 350-400mmElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseModel: WTM-SLR660

Model Name:

Straight line rip sawSpecification:

Working Thickness: 10-90mm

Min. Working Length: 260mm

Max. Working Width: 660mm

Main Motor Power: 15kw

Feeding Motor Power: 2.2kw

Elevation Motor Power: 0.25kw

Total Motor Power: 17.45kw

Feeding Speed: 10-33m/min

Spindle Speed: 3000 rpm

Saw Blade Dia.: 400-450mmElectrical Requirements:

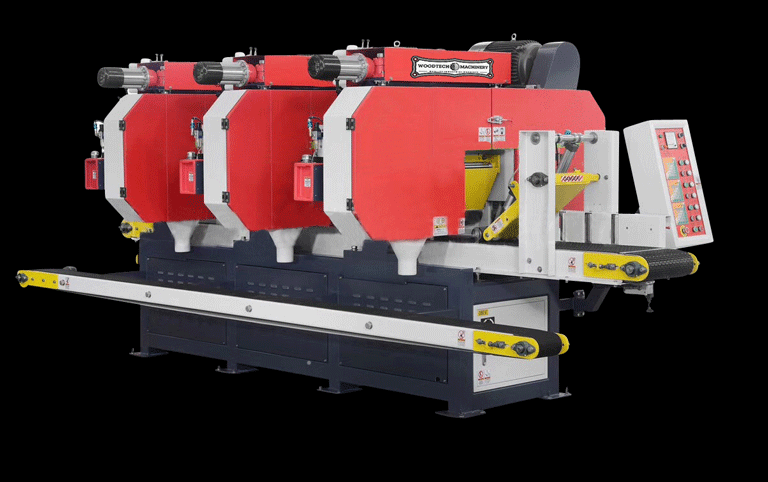

Operating voltage: 460 Volt/60Hz/3 PhaseHorizontal Band Saws

Model:

WTM-400Z2 and WTM-400Z3Model Name:

Two or Three heads HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5-130mm

Width of conveyor belt: 375mm

Diameter of saw roller: 711mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW x 2 or 3 depending on the model

Approx Overall dimension: 2800L x 2200W x 2000HHorizontal Band Saw

Model:

WTM-400ZModel Name:

HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5–160mm

Width of conveyor belt: 375mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW

Overall dimension: 2800L x 2200W x 2000H

Panel Saws

Multi-Blades Panel Saw line

Model:

WTM-1600Multi-Blades Panel Saw:

Main Spindle Dia: 74mmSaw

Blade Diameter: 205mmMax. Working Width:

1600mm Working Thickness: 0-30mm

Main Spindle speed: 2600rpm

Feeding Speed:0-15m/min

Main Motor Power: 22kw

Feeding Motor Power: 1.5kw

Min. Raw Panel Width: 650mm

Rubber Roller: 12pcsAnti-kickback safeguardElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Phase Options:

Semi-automatic hydraulic lifting and receiving table:

Max Weight Loading:3000kgs

Lift Table Size: 1600 X 2400mmAutomatic pusher machine (including CNC lift table):

Automatic push plate stroke: 3000mm

Push plate thickness: 8-100mm

Push speed: 0-25m/min

Frequency conversion motor power:0.75kw

Table Size: 1600*2400 Max Weight Loading: 3000kgs

Feeding Motor Power:3kw

System: Delta PLC control connect Pusher and lift table