Privacy and Messaging Policy

1. Introduction

Welcome to Woodtech Machinery LLC. We are committed to protecting your privacy and ensuring the security of your personal information. This SMS Compliance Privacy Policy outlines how we collect, use, and protect your information when you opt-in to receive SMS communications from us.

2. Information We Collect

When you opt-in to receive SMS communications, we may collect the following information:

- Your mobile phone number

- Your name (if provided)

- Any other information you voluntarily provide

3. How We Use Your Information

We use the information collected to:

- Send you SMS messages related to our products, services, and updates

- Respond to your inquiries and provide customer support

- Improve our services and enhance your experience

4. Consent

By providing your mobile phone number and opting in to receive SMS communications, you consent to receive SMS messages from Woodtech Machinery LLC. You can opt-out at any time by following the instructions provided in the SMS messages or by contacting us directly.

5. Data Security

We implement appropriate technical and organizational measures to protect your personal information from unauthorized access, disclosure, alteration, or destruction.

6. Third-Party Sharing

We do not sell, trade, or otherwise transfer your personal information to outside parties except as described in this policy.

7. Your Rights

You have the right to:

- Access the personal information we hold about you

- Request the correction of inaccurate information

- Request the deletion of your personal information

- Opt-out of receiving SMS communications at any time

8. Changes to This Policy

We may update this SMS Compliance Privacy Policy from time to time. We will notify you of any changes by posting the new policy on our website. Your continued use of our services after any changes indicates your acceptance of the updated policy.

9. Contact Us

If you have any questions or concerns about this SMS Compliance Privacy Policy, please contact us at:

- Email: info@woodtechmachines.com

- Phone: 804.269.9899

SMS Opt-in language

By entering your mobile number and clicking “send”, you agree to receive SMS text messages from Woodtech Machinery LLC at the number provided. Consent is not a condition of purchase. Message and data rates may apply.

Reply HELP for help, STOP to cancel. View our Privacy Policy and Terms of Service.

The Woodtech Difference!

Thank-you for your interest in our quality woodworking machines here at WoodTech Machinery, LLC! A couple points that we would like to bring to your attention! Over the last decade, we have seen a lack of quality woodworking machines available in the market. In an effort to bridge the gap of heavy duty machines, and competitive pricing. Our overseas partnerships enable us to manufacture heavy duty, quality machinery at prices that are affordable.

These machines are built to our specifications, with quality parts that are readily available here in the USA. We have a team of technicians that can service the machines on short notice, and have parts on the shelf ready-to-ship for any issues that may arise.

We provide Plant Layout Consultation, Field Service, and Competitive Financing, to make your next equipment purchase as easy as possible. As a family of lifelong woodworkers, we are proud to offer these quality machines for your production facility.

Please contact us today regarding your woodworking equipment needs.

Home Page

About Us

Letter From the Founder

I wanted to take a moment to say thank you for your interest in our quality woodworking machines. Here are Woodtech Machinery, LLC, we take pride in what we do. Our daily goal is to bring quality woodworking machines to the market, and offer them at a fair and affordable price. Couple that with attentive service, and we feel like we have found a winning combination.

Machinery and woodworking has been in our family for years. My father ran a machine shop for over 40 years building machinery for sawmills and woodworking manufacturing facilities. I personally started and operated a successful wood products company for 14 years. I say that to bring to light the fact that not only are we familiar with machinery, we have also operated these types of machines as a manufacturer over the years. This experience has significantly informed our process in manufacturing quality machines. These machines are products we would be proud of to have in our own manufacturing business.Benjamin Franklin once said – Well done is better than well said. I can sit here at my desk all day, and this paper I'm writing this on will allow me to write anything that I want, But in the end, I would rather humbly ask that you give us the opportunity to work for you, and show you how we can help you with your machinery needs.

From our family to yours!

We wish you many blessings!

Optimizing Saw

Optimizing Saw WTM-CS20x

Wood Dimensions:

Ingoing lengths min./max. 800mm – unlimited

Ingoing widths min./max. 50 – 300mm

Ingoing thicknesses min./max.2 – 12mm

Cross sections max. 300x5mmm max. 150x80mm

Cutting tolerance: +/- 0.5 – +/- 1.5mmCapacity:

Saw cycle: 1-6 times per second (servo drive)

Feed speed infinitely adjustable: 0-120 m/min.

Machine working height: 35”Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Full electrical load: 20.5 kW

Operating load: 8 kW

Operating voltage: 460 Volt/60Hz/3

PhaseAir consumption: approx. 1200 L/min.

Service pressure: approx. 30m/sec

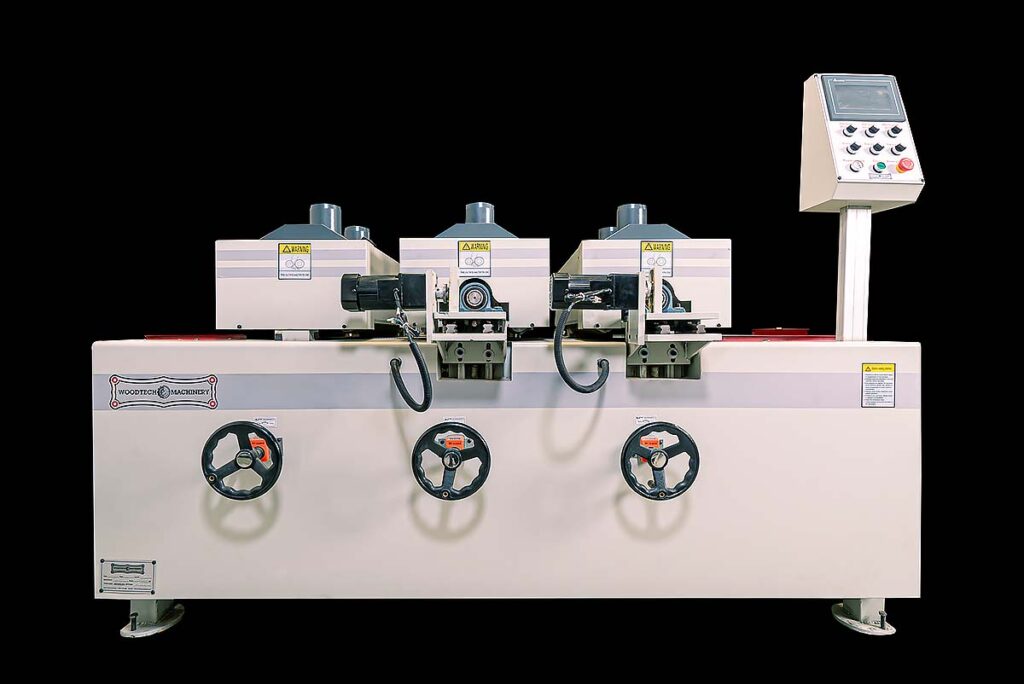

Diameter of dust exhaust ducts: 120mm (2pcs)Denibbing Machine

Model: WTM-UVDB Series

Model Name:

Denibbing/sanding machine. This machine is for denibbing/sanding of wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2-6 head configurations

5. Working height: 800mmFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple sanding grits, and brush lengths available

Optional – Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

In-Line Finish Sander

Model: WTM-UVS Series

Model Name:

In-line finish sanding machineApplication:

Sanding for PU, UV, PE finishesSpecification:

1. Available in 24”, 36”, 51” Widths

2. Workpiece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in single or double head configuration

5. Working height: 800mm

7. Conveyor belt thickness- 5mm

8. Sanding belt size: 60” Length

9. Schneider electronics

10. Variable speed on sanding heads

11. Cleaning brush on the output sideElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseWire Brushing/Denibbing Machine

Model: WTM-UVWB Series

Model Name:

Wire brushing/ Denibbing Sanding MachineApplication:

Wire brushing, embossment, texturing, of the grain in wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in 2-6 head configurationsFeatures:

1. Feed belt thickness 5mm, high temperature resistance fish bone belt.

2. Schneider Electronics

3. Delta frequency converter control each brushing heads individually

4. Adjustable height pressure roller- 2 rolls per head

5. Height counters with individual height adjustment

6. Multiple wire diameter and bristle lengths available

* Optional -Precision automatic lifting motor for height adjustmentElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseGrain Filling Machine

Model: WTM-UVGF Series

Application:

Reverse roll coating for grain fill on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Min working length: 300mm

4. Feeding speed: 5-20m/min

5. Available in single or double head configurationFeature:

1. Italian JMC Aluminum alloy reduction gear drive.

2. Filler scrape wheel equipped with RV reducer to control scraper uniformity.

3. Schneider electronics

4. High-quality coupling transmission. NSK Japanese bearings.

5. Conveyor belt is a 2MM anti-sliding PVC conveyor belt

6. Precision automatic lifting motor for height adjustment

7. All adjustments are fittied with individual countersElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseStain Brushing Machine

Model: WTM-UVBR Series

Model Name:

Stain Brushing MachineApplication:

Specially designed for brushing stain or other finishes on wood furniture, flooring, panels etc.Specifications:

1. Available in 24”, 36”, 51” Widths

2. Work piece thickness: 2-80mm

3. Feeding speed: 5-20m/min

4. Available in 2,3 or 4 head configurations

5. Working height: 800mmFeature:

1. Flat anti-slip solvent resistance belt, belt thickness: 2mm thickness

2. Driving motor 1.5kw Schneider Inverter control

3. The brush heads slide out for easy cleaning.

4. Variable speed drives on each brush.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase