Wide Belt Sanders

WTM-QSG Series Top Surface Sander Triple – Belt Sander Roller + Combination

Features:

Working widths: 24”, 42”, 51”Service side: left

Enclosed MotorsBrush unit for cleaning panels after sandingGeneral Technical Data:

WTM-QSG series machine is a precision sander with a movable feed belt for the thickness setting.

Working thickness: 3/16” – 4”

Minimum working length: 13”

Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units:

Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control. Press rollers assure the flatness of the boards for an even sanding is suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.

-Hard Rubber roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.

-Steel roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.

-Pad can be adjusted up and down.

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configuration

Wide Belt Sanders

Heavy Duty 4 sided Moulder

WTM-DSG Series Bottom Surface Sander

Triple-belt sander roller + combinationFeatures: Working widths: 24”, 42”, 51”

Service side: left Enclosed Motors

Brush unit for cleaning panels after sandingGeneral technical data: WTM-DSG series machine is a constant pass-line, bottom sanding machine, it is specially designed for a sanding line with a fixed height.Working thickness: 3/16” – 4”

Minimum working length: 13”

Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units: Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control.

Press rollers assure the flatness of the boards for an even sanding Is suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.

-Hard Rubber roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.

-Steel roller is available. (optional)

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.

-Pad can be adjusted up and down.

-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configurationWide Belt Sander

WTM-FSG Series Constant Pass-Line, Top Surface Sander

Triple-belt sander roller + combinationFeatures:

Working widths: 24”, 42”, 51”

Service side: left

Enclosed Motors

Brush unit for cleaning panels after sandingGeneral technical data:

WTM-FSG series machine is a constant pass-line sanding machine, it is specially designed for a sanding line with a fixed height

Working thickness: 3/16” – 4”

Minimum working length: 13”Feeding speed: 0-80 F/min

Compressed air consumption: 1.5 CBM/min

Overall dimension: 94”x82x80”

Drives from main motors to sanding heads are run with V-belts and pulleys, Heavy Duty disk brakes for emergency stop.Pressure Units:

Pressure units to hold the work pieces on the feed belt; are positioned in front and rear of each sanding head: independent variable pressure control.Press rollers assure the flatness of the boards for an even sandingIs suitable for short piecesSteel press shoes are optional.

1st head roller is steel with helical grooves for cooling.-Hard Rubber roller is available. (optional)-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

2nd head roller is Rubber with helical grooves for cooling.-Steel roller is available. (optional)-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.

The 3rd sanding head is a combination of roller and pad.-Pad can be adjusted up and down.-Oscillating air jet blowers for sanding belt cleaning, complete with dust hood.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

** Also available in a Double Head configurationPUR Glue Line

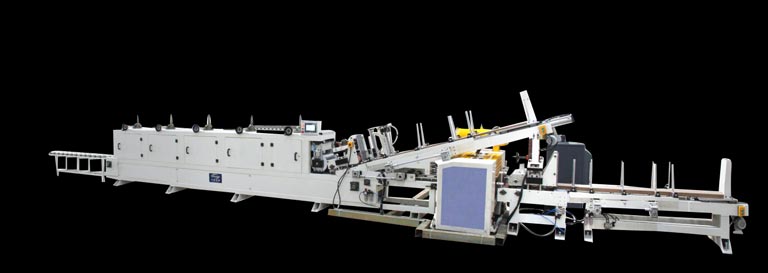

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

2-3 -4 sections pressing rolls: AluminumHorizontal Band Saws

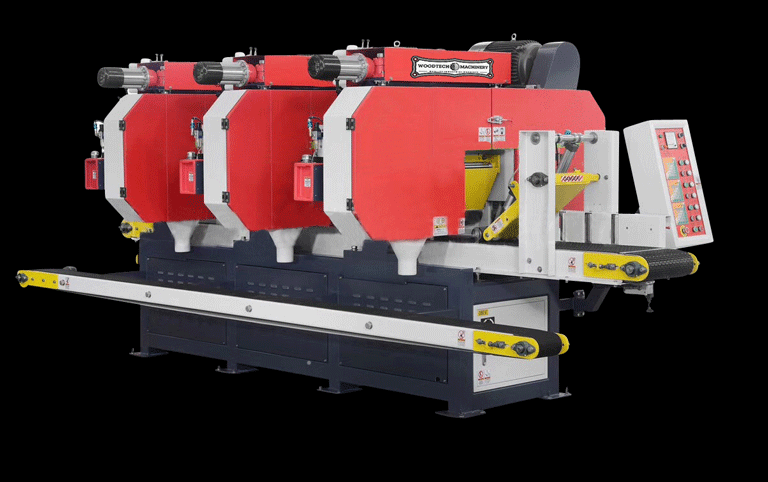

Model:

WTM-400Z2 and WTM-400Z3Model Name:

Two or Three heads HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5-130mm

Width of conveyor belt: 375mm

Diameter of saw roller: 711mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW x 2 or 3 depending on the model

Approx Overall dimension: 2800L x 2200W x 2000HHorizontal Band Saw

Model:

WTM-400ZModel Name:

HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5–160mm

Width of conveyor belt: 375mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW

Overall dimension: 2800L x 2200W x 2000H