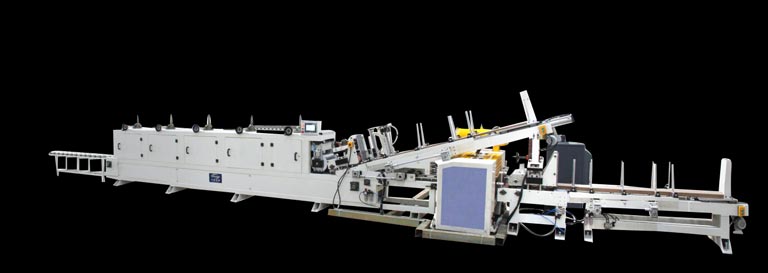

Reciprocal Spray Line

Automatic Reciprocal Spraying Machine

Model:

WTM-SP2500Specifications:

Max. working width: 1300mm

Max. working length: 2440mm

Max.spraying thickness: 150mmSpraying guns: 8

Working pressure: 06-0.8Mpa

Total power: 10.85kwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhasePUR Glue Line

PUR Glue Melter

Model:

WTM-PUR-120Specifications:

27kg/hour Application guns: 2

Size: 560x340x635mm

Main power: 7.8kwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Motor rorating: 0.5-60/minPUR Glue Line

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

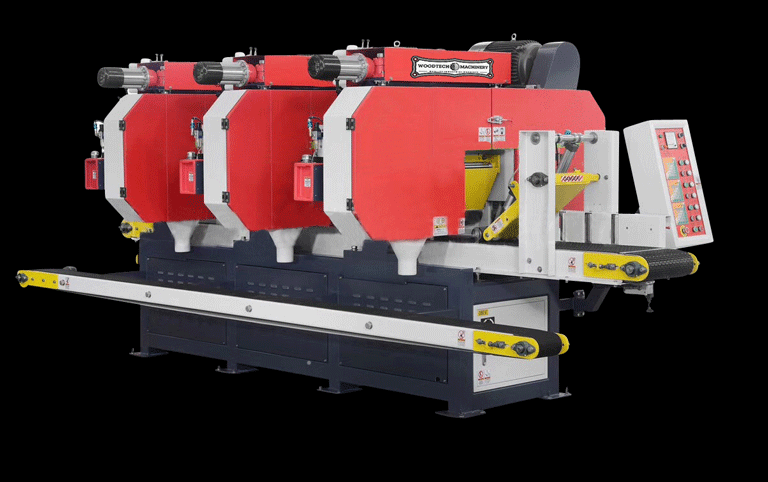

2-3 -4 sections pressing rolls: AluminumHorizontal Band Saws

Model:

WTM-400Z2 and WTM-400Z3Model Name:

Two or Three heads HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5-130mm

Width of conveyor belt: 375mm

Diameter of saw roller: 711mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW x 2 or 3 depending on the model

Approx Overall dimension: 2800L x 2200W x 2000HHorizontal Band Saw

Model:

WTM-400ZModel Name:

HD Horizontal Band Saw

Max. workpiece size: 300mm

Thickness of production board: 5–160mm

Width of conveyor belt: 375mm

Diameter of saw wheel: 711mm

Feeding speed: 0-15m/min

Hydraulic pressure: 50-60kg/cm

Size of saw blade: 185”

Length, 2” wide, 1.6mm thickElectrical Requirements:

Voltage: 460V/60 HZ/3 phase

Full electrical load: 18.5 KW

Overall dimension: 2800L x 2200W x 2000H

Panel Saws

Multi-Blades Panel Saw line

Model:

WTM-1600Multi-Blades Panel Saw:

Main Spindle Dia: 74mmSaw

Blade Diameter: 205mmMax. Working Width:

1600mm Working Thickness: 0-30mm

Main Spindle speed: 2600rpm

Feeding Speed:0-15m/min

Main Motor Power: 22kw

Feeding Motor Power: 1.5kw

Min. Raw Panel Width: 650mm

Rubber Roller: 12pcsAnti-kickback safeguardElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Phase Options:

Semi-automatic hydraulic lifting and receiving table:

Max Weight Loading:3000kgs

Lift Table Size: 1600 X 2400mmAutomatic pusher machine (including CNC lift table):

Automatic push plate stroke: 3000mm

Push plate thickness: 8-100mm

Push speed: 0-25m/min

Frequency conversion motor power:0.75kw

Table Size: 1600*2400 Max Weight Loading: 3000kgs

Feeding Motor Power:3kw

System: Delta PLC control connect Pusher and lift tableDouble End Tenoner

Heavy Duty 4 sided Moulder

Model:

WTM-D80Specifications:

8 Spindles – multiple configurations

Working Thickness – 10mm-120mm

Working Width – 250mm-2500mmElectrical Requirements:

Full electrical load: 44kW

Operating voltage: 460 Volt/60Hz/3 Phase

* ask for additional detailsMoulders

Heavy Duty 4 sided Moulder

Models:

WTM-330 – 12” wide – available in 4, 5 or 6 head configurations.

WTM-260- 10” wide – available in 4, 5 or 6 head configurations.

WTM-230 – 9” wide – available in 4, 5 or 6 head configurations.

WTM-200 – 7” wide – available in 4, 5 or 6 head configurations.Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseFeatures Available:

Outboard bearings *on WTM-330 Pneumatic hold-downs, and side pressure

PLC controlled – LCD readout Heavy duty drive motors

Belt driven spindles

Auto Lubrication

Plus many more…