Optimizing Saw

Optimizing Saw WTM-CS20x

Wood Dimensions:

Ingoing lengths min./max. 800mm – unlimited

Ingoing widths min./max. 50 – 300mm

Ingoing thicknesses min./max.2 – 12mm

Cross sections max. 300x5mmm max. 150x80mm

Cutting tolerance: +/- 0.5 – +/- 1.5mmCapacity:

Saw cycle: 1-6 times per second (servo drive)

Feed speed infinitely adjustable: 0-120 m/min.

Machine working height: 35”Electrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Full electrical load: 20.5 kW

Operating load: 8 kW

Operating voltage: 460 Volt/60Hz/3

PhaseAir consumption: approx. 1200 L/min.

Service pressure: approx. 30m/sec

Diameter of dust exhaust ducts: 120mm (2pcs)PUR Glue Line

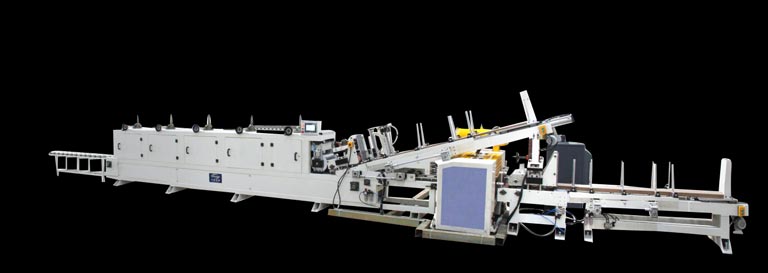

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

2-3 -4 sections pressing rolls: Aluminum