Industrial PUR Glue Line

Wide-Belt Sander Subhead

Copy: Our industrial PUR Glue Line features a wide range of working widths, adjustable working thickness, infeed and outfeed, heavy-duty hinged access doors, intuitive/durable control panel, leveling feet, lift points, and are available in double, or triple head configurations.

Safety features include emergency stop. (see individual product pages for additional specifics)PUR Glue Line Electrical Requirements: Operating voltage: 460 Volt/60Hz/3 Phase (check with us for other options).

Our PUR Glue Line Equipment

- PUR Glue Line

- PUR Glue Line page 2

PUR Glue Line

PUR Glue Melter

Model:

WTM-PUR-120Specifications:

27kg/hour Application guns: 2

Size: 560x340x635mm

Main power: 7.8kwElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 PhaseElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3

Motor rorating: 0.5-60/minPUR Glue Line

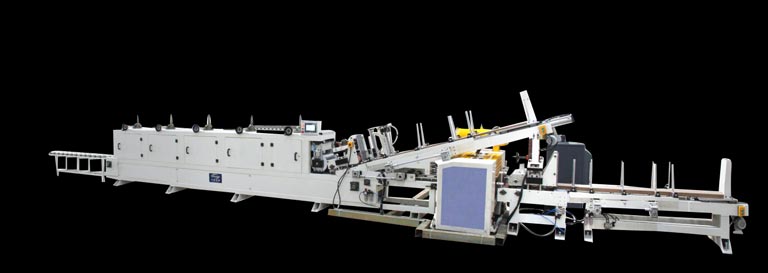

PUR Automatic Floor Laminating Line

Model – WTM-PUR-350

Specifications:

Working width: 100–350mm

Plywood thickness: 9-18mm

Feed Speed: 5-15m/minAir consumption: 0.1 CBM/min

Approx overall Dimensions: 17.4L x 1.6W × 1.4HElectrical Requirements:

Operating voltage: 460 Volt/60Hz/3 Phase

Glue Spreader:

Silicon Rubber Roller: 0.75KW X 2

Lifting motor: 0.37KW

Dosing Roller: 0.37KW

Heating Power: 3KW X 2 (Oil heating)

Coating Roller: 240×500

SiliconDosing roller: 216×500

Chrome Electrical thickness adjustment

Manual glue thickness control

Pinch Roll: Chain Drive Drive Power: 4kw Manual thickness control

Pneumatic pressure, 4 sections

First section pressing rolls: rubber with 40 Durometer

2-3 -4 sections pressing rolls: Aluminum